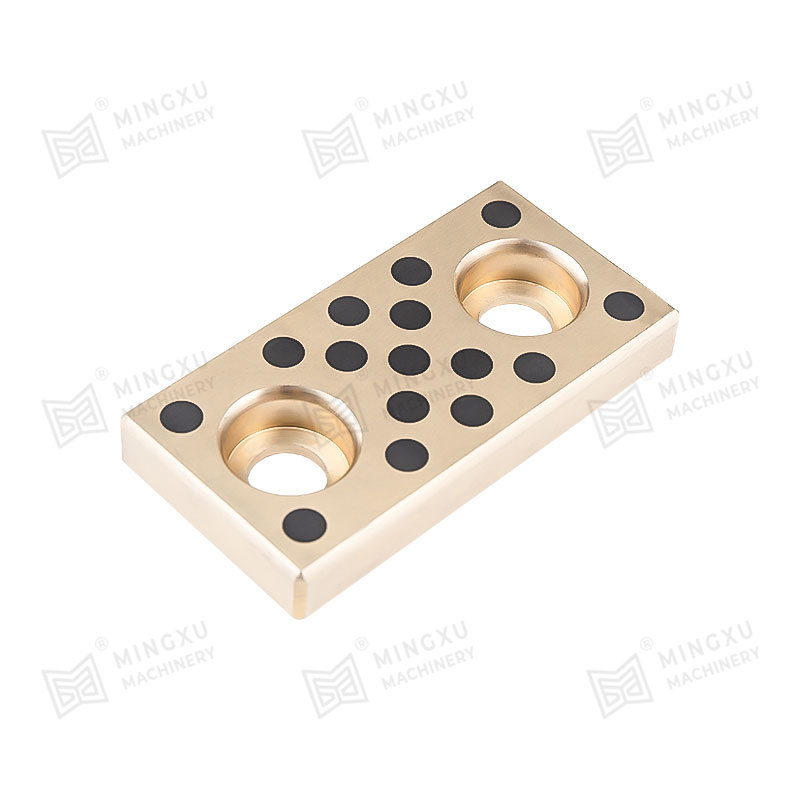

Sesendal Gangsa Bertatah Grafit ISO MXB-JDB

Cat:Pengeluar Galas Pelincir Sendiri

Galas pelincir diri MXB-JDB, juga dikenali sebagai sesendal gangsa bertatahkan grafit, adalah galas pelincir baru yang mempunyai kedua-dua ciri gal...

Lihat butiranAdvancements in solid lubricant materials are critical for enhancing the performance of solid-lubricating bearings in high-speed applications. High-speed environments pose challenges like increased frictional heat, wear, and reduced efficiency, requiring innovative solutions. Here are some key advancements:

Nanotechnology in Solid Lubricants

Nanocomposites: Combining traditional solid lubricants like graphite or molybdenum disulfide (MoS₂) with nanoparticles (e.g., graphene, carbon nanotubes) can enhance their thermal stability and wear resistance.

Benefits for Bearings: Solid-lubricating bearings with nanocomposite coatings can operate more effectively at high speeds due to lower friction and better heat dissipation.

High-Temperature Solid Lubricants

Ceramic-Based Lubricants: Advanced ceramics, such as silicon nitride or boron nitride, offer excellent high-temperature stability and low friction, making them ideal for high-speed applications.

Benefits for Bearings: Bearings made with or coated in these materials maintain lubrication properties even at the elevated temperatures generated by high-speed operation.

Metal Matrix Composites (MMC)

Lubricant Integration: Embedding solid lubricants (e.g., MoS₂ or graphite) directly into a metal matrix provides a strong, durable bearing material with self-lubricating properties.

Benefits for Bearings: This design improves wear resistance and ensures consistent lubrication even under high rotational speeds and loads.

Polymer Innovations

Enhanced Polytetrafluoroethylene (PTFE): Modified PTFE with additives like glass fibers or carbon increases durability and reduces wear at high speeds.

Polymer Composites: New polymer blends infused with solid lubricants are being developed to combine flexibility, low friction, and high-speed performance.

Benefits for Bearings: These materials make solid-lubricating bearings lighter, quieter, and capable of withstanding the stresses of rapid motion.

Adaptive Solid Lubricants

Phase-Changing Materials: Some modern solid lubricants can change their structure at high temperatures or pressures to provide optimal lubrication dynamically.

Benefits for Bearings: These adaptive properties ensure that solid-lubricating bearings perform well across a range of operating speeds and conditions.

Surface Engineering and Coatings

Diamond-Like Carbon (DLC) Coatings: DLC coatings on solid-lubricating bearings reduce wear and friction significantly, even at very high speeds.

Advanced Plasma Spraying: This technique can deposit uniform, high-performance solid lubricant coatings on bearing surfaces, enhancing their durability and speed capabilities.

Hybrid Lubrication Approaches

Combination Systems: Bearings with both solid lubricant layers and microchannels for emergency liquid lubrication are being developed for ultra-high-speed applications.

Benefits for Bearings: This hybrid approach provides the stability of solid lubrication with added lubrication for extreme conditions.

Future Potential

The development of these materials is paving the way for solid-lubricating bearings that can:

Handle higher speeds without increasing maintenance requirements.

Operate in extreme conditions like aerospace, where high rotation rates and temperature variations are common.

Provide consistent performance and long lifespan, even under dynamic stresses.

Galas pelincir diri MXB-JDB, juga dikenali sebagai sesendal gangsa bertatahkan grafit, adalah galas pelincir baru yang mempunyai kedua-dua ciri gal...

Lihat butiran

Galas gangsa tuangan pelincir sendiri MXB-JDBUF menggabungkan kelebihan reka bentuk pelincir sendiri dan bebibir. Bahan mentah diperbuat daripada b...

Lihat butiran

Peralatan yang digunakan dalam jentera perlombongan tertakluk kepada haus dan lusuh yang serius. Untuk memanjangkan hayat perkhidmatan peralatan, p...

Lihat butiran

Plat haus pelincir sendiri MXB-JOLP mempunyai ciri pelincir sendiri yang baik dan tidak memerlukan pelinciran luaran. Produk ini mempunyai kapasiti...

Lihat butiran

Plat tahan haus pelincir sendiri MXB-JTLP boleh menyediakan produk standard antara lebar dari 18mm hingga 68mm dan panjang dari 100mm hingga 220mm....

Lihat butiran

Rel panduan pelincir sendiri MXB-JTGLW memberikan rintangan dan mengurangkan geseran, memastikan ketahanan yang dilanjutkan dan prestasi yang diper...

Lihat butiran

SF-1B bronze basic bearing is made of tin bronze as the base, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature res...

Lihat butiran

SF-1SS is a highly corrosion-resistant and wear-resistant bearing made of stainless steel as the base material and PTFE sprayed on the surface. This m...

Lihat butiran

SF-1T is a special formula product designed for high PV value working conditions of gear oil pump. The product has special advantages of fatigue resis...

Lihat butiran

SF-1P reciprocating bearing is a novel formula product designed based on the structure of SF-1X material and according to the special common condition...

Lihat butiran

Hubungi Kami